Adjustable Speed Drives –

(a.k.a. Variable Speed Drives)

What They Are, How They Work

Application Information

- Adjustable Speed Drives – Application Information

- DC Drives – Principles of Operation

- DC Drive Types

- DC Motor Control Characteristics

- AC Drives – Principles of Operation

- AC Controller Types

- AC Motor Control Characteristics

- Motor Selection

- AC vs. DC Drive Comparison

- Basic Mechanics

- Other Application Factors

- Measuring Machine Torque

- Mechanical Formulas

DC MOTOR CONTROL CHARACTERISTICS

A shunt-wound motor is a direct-current motor in which the field windings and the armature may be connected in parallel across a constant-voltage supply. In adjustable speed applications, the field is connected across a constant-voltage supply and the armature is connected across an independent adjustable-voltage supply. Permanent ma

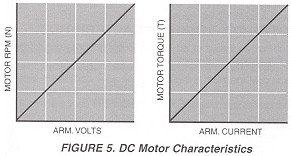

The speed (N) of a DC motor is proportional to its armature voltage; the torque (T) is proportional to armature current, and the two quantities are independent, as illustrated in Figure 5.

CONSTANT TORQUE APPLICATIONS

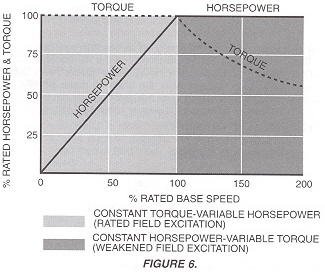

Armature voltage controlled DC drives are constant torque drives. They are capable of providing rated torque at any speed between zero and the base (rated) speed of the motor as shown by Figure 6. Horsepower varies in direct proportion to speed, and 100% rated horsepower is developed only at 100% rated motor speed with rated torque.

CONSTANT HORSEPOWER APPLICATIONS

Armature Controlled DC Drives – Certain applications require constant horsepower over a specified speed range. The screened area, under the horsepower curve in Figure 6, illustrates the limits of constant horsepower operation for armature controlled DC drives. As an example, the motor could provide constant horsepower between 50% speed and 100% speed, or a 2:1 range. However, the 50% speed point coincides with the 50% horsepower point. Any constant horsepower application may be easily calculated by multiplying the desired horsepower by the ratio of the speed range over which horsepower must remain constant. If 5 HP is required over a 2:1 range, an armature only controlled drive rated for 10 (5 x 2) horsepower would be required.

Table 3 provides a convenient listing of horsepower output at various operating speeds for constant torque drives.

Field Controlled DC Drives – Another characteristic of a shuntwound DC motor is that a reduction in field voltage to less than the design rating will result in an increase in speed for a given anmature voltage. It is important to note, however, that this results in a higher armature current for a given motor load. A simple method of accomplishing this is by inserting a resistor in series with the field voltage source. This may be u

Adjustable Speed Drive Application Information provided by: FINCOR Automation