Low voltage DC drives

ABB DC Drives

DCS800, 10 to 4000 hp

Power Converter Modules

Enclosure Rating

The DCS800-S0x power converter module carries a NEMA TYPE OPEN (IP00) rating and must be mounted in a protective enclosure. There are seven different frame sizes, D1 through D7, graduated in terms of current and voltage.

Regenerative and Non-Regenerative Drives

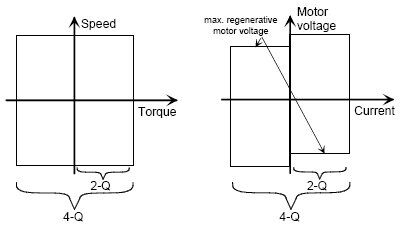

Non-regenerative (2-Q) power converter modules are used when motor torque and speed are always in the same direction and when significant stopping power is not required.

This is ideal for applications such as:

- Fan or blower

- Mixer

- Pump

- Extruder

It is not possible for a 2-Q drive to slow down an inertial load.

The load will stop only due to friction, windage, or another form of load resistance. It is also not possible for a non-regenerative drive to reverse direction unless field reversal is used.

Regenerative (4-Q) power converter modules are used when motor torque can occur in either direction. This is for applications such as:

- Stop-start conveyor

- Draw Roll

- Rolling mill

- Unwinder

- Overhead crane hoist

A 4-Q drive is able to start and stop an inertial load in both forward and reverse directions.

Field Power Supplies and Fusing

Converter modules sizes D1 through D5 are equipped with fused internal field power supplies. Sizes D6 – D7 require an external field power supply. See page 21 for details.

AC line fuses and DC armature fuses must be separately mounted. See page 24 for fuse information as well as information on other optional system components.

AC line fuses to be separately mounted on sizes D1 – D4.

They are included internally on D5 – D7. DC armature fuses are needed for all 4-Q drives and are to be separately mounted.

See page 26 for fuse recommendations as well as specifications for other external system components.

Voltage Selection

The output voltage of the drive depends on the incoming AC line voltage and whether a 2-Q or 4-Q drive is selected. The table below shows the maximum output voltage that will result for various input voltages for both the 2-Q and 4-Q drives.

| System input AC line voltage | DC voltage (recommended) | Ideal DC voltage without load | Recommended DCS800 voltage class type code | |

| 2Q | 4Q | |||

| UVN [V] | Udmax 2-Q [V] | Udmax 4-Q [V] | Udi0 [V] | |

| 230 | 265 | 240 | 310 | 05 |

| 380 | 440 | 395 | 510 | 05 |

| 400 | 465 | 415 | 540 | 05 |

| 415 | 480 | 430 | 560 | 05 |

| 440 | 510 | 455 | 590 | 05 |

| 460 | 530 | 480 | 620 | 05 |

| 480 | 555 | 500 | 640 | 05 |

| 500 | 580 | 520 | 670 | 05 |

| 525 | 610 | 545 | 700 | 05 (D1-D4), 06 |

| 575 | 670 | 600 | 770 | 06 |

| 600 | 700 | 625 | 810 | 06 |

| 660 | 765 | 685 | 890 | 07 |

| 690 | 800 | 720 | 930 | 07 |

| 800 | 915 | 820 | 1060 | 08 |

| 990 | 1160 | 1040 | 1350 | 10 |

| 1200 | 1380 | 1235 | 1590 | 12 |

The maximum output voltage of a 4-Q drive can be increased up to the level of Udmax 2-Q if the torque reversal time from motor to regenerative mode is set above 300 ms.

Low Mains Voltage – (30 to 120 V) SDCS-SUB-4 (+S186)

External DC Voltage Measurement – Measures Vdc at the motor; (D1-D4) SDCS-UCM-1; (not needed D5-D7)

Analog, Digital and Encoder Interface

The drive is equipped with high-speed, high-resolution analog inputs and outputs to interface with user signals. Analog inputs are 16-bit resolution (15 plus one sign bit) which is the highest resolution in the industry.

The following interfaces are standard features:

- Analog DC tachometer

- Pulse encoder

- Motorized pot, speed pot and up to two analog meters

Optional modules are available to increase the number of analog, digital, tachometer, and encoder interfaces and to add isolated interfaces for temperature sensors and other devices.

Specifications subject to change without notice.

ABB DCS800 DC Variable Speed Drives