Adjustable Speed Drives –

(a.k.a. Variable Speed Drives)

What They Are, How They Work

Application Information

- Adjustable Speed Drives – Application Information

- DC Drives – Principles of Operation

- DC Drive Types

- DC Motor Control Characteristics

- AC Drives – Principles of Operation

- AC Controller Types

- AC Motor Control Characteristics

- Motor Selection

- AC vs. DC Drive Comparison

- Basic Mechanics

- Other Application Factors

- Measuring Machine Torque

- Mechanical Formulas

DC DRIVES – PRINCIPLES OF OPERATION

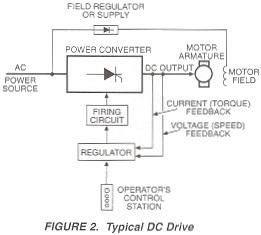

DC drives, because of their simplicity, ease of application, reliability and favorable cost have long been a backbone of industrial applications. A typical adjustable speed drive using a silicon controller rectifier (SCR) power conversion’ section, common for this type unit, is shown in Figure 2. The SCR, (also termed a thyristor) converts the fixed voltage alternating current (AC) of the power source to an adjustable voltage, controlled direct current (DC) output which is applied to the armature of a DC motor.

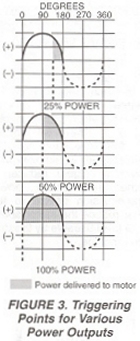

SCR’s provide a controllable power output by “phase angle control”, so called because the firing angle (a point in time where the SCR is triggered in

Adjustable Speed Drive Application Information provided by: FINCOR Automation