PLEASE NOTE: Effective 2019, we no longer supply Control Techniques variable frequency drives and components. We have drives from several other manufacturers which can meet or exceed the performance characteristics of the Control Techniques line. Simply complete the form below, or contact us with the model of your current or obsolete Control Techniques drive and we’ll be glad to identify a suitable replacement.

Also, the Fincor and Saftronics lines of AC variable frequency drives, DC variable speed drives, and reduced voltage starters were once owned by Emerson but have been obsolete for several years. However, we have many years’ experience working with these drives and can quickly identify replacements capable of exceeding the quality and performance of these older drive technologies. For a suitable replacement, fill out the form below or contact us with your drive or application requirements, and we’ll handle it from there!

|

(Obsolete) Saftronics PC10 Mini Vector AC Drives

(Obsolete FINCOR Series 5750)

Saftronics PC10 AC Drives are Obsolete and No Longer Available – They have been Replaced with the Saftronics CV10 Compact Vector AC Drives.

- Saftronics PC10 Mini Vector AC Drives – Part Numbers, Pricing, Dimensions & Weights

- Options & Accessories

- Dynamic Braking

- Drive Ratings Efficiency and Watts Loss

- Standard Specifications

- Dimension Sheets

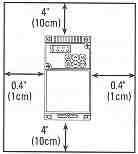

- NEMA 1 Kit Dimensions

- Basic Wiring Diagram

Standard Specifications

| Environmental Conditions | |

|

|

|

| Enclosure | Protected Chassis (lP20) and NEMA 1 |

|

|

|

| Installation Location | NEMA 1 Intended for indoor use only, less than 1,000 meters (3,300 feet) elevation, not in contact with corrosive gas, oil mist, dust or direct sunlight.Free from corrosive gases, flammable gases, oil mist, dust and direct sunlight. Indoor use only. |

|

|

|

| Altitude | 1000m or less. Applicable to 3000m with power derating (-10%/1 OOOm) |

|

|

|

| Ambient Temperature | -10 to +50°C (+ 14°F to 122°F) |

|

|

|

| Ambient Humidity | 5 to 95% RH (non-condensing) |

|

|

|

| Vibration | 3mm: 2 to less than 9 Hz 9.8 m/s2: 9 to less than 20 Hz 2 m/s2: 20 to less than 55 Hz 1 m/s2: 55 to less than 200 Hz |

|

|

|

| Storage Condition | Temperature: -25°C to +65°C (-4°F to 149°F) Humidity: 5 to 95% RH (non-condensing) |

|

|

|

| Input | |

|

|

|

| Rated Input AC Voltage | 200 to 230 Vac 50/60 Hz, 3 phase (1/8 to 10 hp) 380 to 480 Vac 50/60 Hz, 3 phase (1/2 to 10 hp) Voltage: -15% to +10%; voltage unbalance: within 3%; frequency::!: 5% |

|

|

|

| Output | |

|

|

|

| Setting | Maximum frequency: 50 to 400 Hz Base frequency: 25 to 400 Hz Starting frequency: 0.1 to 60.0 Hz; holding time: 0.0 to 10.0s Carrier frequency: 0.75 to 15kHz |

|

|

|

| Accuracy (Stability) | Digital setting: +0.01 % of maximum frequency (from -10°C to +50°C) Analog setting: +0.2% of maximum frequency (at 25°C +10°C) |

|

|

|

| Setting Resolution | Digital setting: 0.01 Hz at maximum frequency up to 99.99 Hz, (0.1 Hz at maximum frequency of 100.0 Hz and above) Analog setting: 1/3000 of maximum frequency (ex. 0.02 Hz at 60 Hz, 0.04 Hz at 120 Hz, 0.15 Hz at 400 Hz) Link setting: 1/20000 of maximum frequency or 0.01 Hz fixed (ex. 0.003 Hz at 60 Hz, 0.006 Hz at 120 Hz, 0.02 Hz at 400 Hz,) |

|

|

|

| Control | |

|

|

|

| Control Method | V/f control (sinusoidal PWM control) Dynamic torque vector control (sinusoidal PWM control) |

|

|

|

| Operation Method | Keypad operation: RUN or STOP key Digital input signal: Forward/Reverse command, Coast-to-Stop command, etc. Link operation: RS485 (standard), Profibus-DP, Interbus-ST”, DeviceNef” , Modbus PlusT”, CAN Open (option) |

|

|

|

| Frequency Setting | Keypad operation: UP or DOWN keys External potentiometer of 1 to 5k ohm Analog input: 0 to +10 Vdc (0 to +5 Vdc) , 4 to 20 mA dc Multistep frequency: up to 16 different frequencies can be selected by digital input signal Link operation: RS485 (standard) Profibus-DP, Interbus-ST”, DeviceNet'”, Modbus PlusT”, CAN Open (option) |

|

|

|

| Acceleration/Deceleration Time | 0.01 to 3600s (independently adjustable acceleration and deceleration, 2 different times are selectable) |

|

|

|

| Voltage/Frequency (V /F) Characteristics |

Adjustable at base and maximum frequency with AVR control: 320 to 480V (460V series). 80 to 240V (230V series) |

|

|

|

| Restart After Momentary Power Failure | Drive restarts without causing the motor to stop if the automatic restart is specified for the drive |

|

|

|

| Frequency Limiter | High and low limits can be preset |

|

|

|

| Bias Frequency | Bias frequency can be preset (-400 to +400 Hz) |

|

|

|

| Jump Frequency Control | Jump frequency (3 points) and its common jump hysteresis width (0 to 30 Hz) can be preset |

|

|

|

| Torque Boost | Selectable by load characteristics: constant torque load (auto/manual), variable torque load (manual) |

|

|

|

| Protection | |

|

|

|

| Overload | Protects the drive by electronic thermal and detection of drive temperature |

|

|

|

| Overvoltage | Detects dc link circuit overvoltage to stop drive (460V series: 800 Vdc, 230V series: 400 Vdc) |

|

|

|

| Overheating | Protects the drive by detection of drive temperature |

|

|

|

| Motor Overload | Electronic thermal overload relay can be selected for standard motor or drive motor |

|

|

|

| Motor Protection by PTC Thermistor | When the motor temperature exceeds allowable value, the drive trips automatically |

|

|

|

| Options | |

|

|

|

| Standard | EMI Filters, DB Resistors |

|

|

|

| Communications | Profibus-DP, Interbus-ST”, DeviceNet'”, Modbus PlusT”, CAN Open (option) |

|

|

|

| Mounting Space | |