Dynapar

Innovation, Customization, Delivery

Dynapar encompasses the broadest line of trusted brands in motion feedback control, including Dynapar encoders and Hengstler brand incremental encoders and absolute rotary encoders, Northstar heavy-duty magneto-resistive and Heavy-Duty optical encoders and high-performance Harowe brand resolvers. Only Dynapar feedback solutions offer these world-class rotary feedback brands from one Global Supplier with 3 day delivery on most models for customer peace of mind.

Joliet Technologies is the preferred Dynapar Integrator for the Chicagoland area.

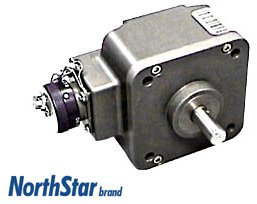

Series HD25 Optical Encoder – Harsh Duty

Series HD25 Optical Encoder – Harsh Duty

Quick Specs…

- Single or dual output

- Optional high current line driver

- ATEX certification available for intrinsically safe application

- High resolution unbreakable disk

- Industrial Duty Latching Connector

- NEMA 4 / IP67 Rated

- Nickel or stainless steel housing available

- Two Year Warranty

Overview / Design Principle:

Northstar’s HD25 Harsh Duty Optical Encoder is a compact, Industrial Hubshaft encoder designed to exceed IP66/67 and NEMA 6 enclosure requirements. It is also available in stainless steel that exceeds NEMA 4X and NEMA 6P requirements and is ideal for stringent washdown environments, including those where high pressures team or caustic chemicals are needed to meet regulatory requirements.

The HD25 features 100lb axial and radial bearings, -40 to 100 C temperature range and a unique labyrinth double sealed housing and optional dual “redundant” outputs that are covered by a two-year warranty (one year for bearings). Northstar’s traditional quality, reliability and value are built-in every HD20 encoder.

Also available in this series is an intrinsically-safe version certified to ATEX EEX IA IIB T4 used with the appropriate IS barrier. Accessory barriers can be supplied with the encoder.

Features and Benefits:

Mechanical and Environmental

- Unbreakable code disks for 1 to 5000 PPR

- Flexible mounting

- Heavy-duty shaft seals

- Sealed connector – no soldering

Electrical

- Cast housing maximizes noise immunity and durability

Applications/ Industries:

The HD25 harsh duty encoder is ideal for machine applications with corrosive environments that demand heavy washdown protection. This compact, special duty encoder is designed to excede IP66/IP67 and NEMA 6 enclosure requirements with a PPR range through 5000. ATEX certification is also available for intrinsically safe applications.

- Converting Machinery

- Material Handling

- Packaging Equipment

- Pickling Equipment

- Processing Equipment

- Chemical

- Oil & Gas

Specifications:

Standard Operating Characteristics

Code: Optical Incremental

Pulses per Revolution: 1-5000

Phasing Sense: A leads B for Clockwise rotation (CCW) viewing shaft rotation viewing the shaft clamp end of the encoder

Quadrature Phasing: 90° ± 15°

Symmetry: 180° ± 18°

Index: 180° ± 18°

Electrical

Input Voltage Requirement: 5-26 Volts VDC; 5-15 VDC; 5DVC; 7-26VDC (ATEX)

Current Requirement: 50 mA typical plus line driver load

Output Signals: With Elec Option 0, 1, 2, 4, A & B: 5-26 V Line Driver, 40mA

With Elec Option 3: 5 V Line Driver, 40mA

With Elec Option 5: 5 V Line Driver, 100mA

With Elec Option 6: 5-15 V Line Driver, 100mA

Frequency Response: 0 – 125kHz Data & Index

Electrical Immunity: 1kV ESD, Reverse Polarity, Short Circuit

Connector: 6,7 or 10 pin style MS3 connectors available; 18″ cable exit with seal

Mechanical

Shaft Speed: 3,600 RPM; Max up to 6000 RPM

Mounting Configuration: Flexible mount with anti-rotation arm

Housing Material: Anodized aluminum, stainless steel or nickel plated version available

Available Shaft Sizes: 3/8″ or 10mm available. See ordering table for sizes.

Allowable Shaft End-Play: ± 0.050”

Allowable Shaft Runout: 0.025” TIR (Subject to RPM Limitation)

Environmental

Operating Temperature Range: -40°C to +100°C; -40°C to +80°C (ATEX)

Storage Temperature Range: -40°C to +100°C

Humidity: to 98% RH (non-condensing)

Shock: 50 Gs for 11 ms

Vibration: 20 Gs @ 5-2000 Hz spectrum

Available Specifications:

- Series HD25 (PDF file)

Related Products & Resources:

- Spare Parts & Accessories

- NEW Northstar Line Brochure (PDF file)

- Feedback Quick Reference Guide (PDF File)

- Encoder Catalog (PDF file)

- Encoder Handbook (PDF file)

- Encoder FAQ’s

For additional information or to receive a full-line catalog, contact your Dynapar representative at 1.800.873.8731 or visit their web site at: www.dynapar.com

Headquarters:1675 Delany Road • Gurnee, IL 60031-1282 • USA

Phone: 1.847.662.2666

Fax: 1.847.662.6633

Email: custserv@dynapar.com or dynapar.techsupport@dynapar.com

© 2009 Dynapar Corp. Printed in U.S.A. • Feedback Quick Reference Guide P/N# N-FLB130 (11/09) 5M

Call Joliet Technologies TODAY

If you have any questions concerning Dynapar products, feel free to contact us:

Phone (815) 725-9696,

Toll Free (866) 492-9888,

Fax (815) 725-9393 or

E-mail info@joliettech.com

Joliet Technologies custom packages, integrates and engineers AC Variable Frequency Drives (VFD), DC Variable Speed Drives (VSD) and AC Drive Controllers using top of the line manufacturers, like ABB, Emerson-Control Techniques, Siemens and Saftronics (Fincor). Our custom drive packages are built to your specifications for your application. We specialize in large horsepower drive systems (500Hp and above). Call us at (815) 725-9696 or fax us at (815) 725-9393 or e-mail us or fill out an RFQ with your requirements. Serving the greater Chicagoland area and the World.

Series HD25 Optical Encoder – Harsh Duty

Series HD25 Optical Encoder – Harsh Duty