Adjustable Speed Drives –

(a.k.a. Variable Speed Drives)

What They Are, How They Work

Application Information

- Adjustable Speed Drives – Application Information

- DC Drives – Principles of Operation

- DC Drive Types

- DC Motor Control Characteristics

- AC Drives – Principles of Operation

- AC Controller Types

- AC Motor Control Characteristics

- Motor Selection

- AC vs. DC Drive Comparison

- Basic Mechanics

- Other Application Factors

- Measuring Machine Torque

- Mechanical Formulas

BASIC MECHANICS

The curve in Figure 6 shows a distinct relationship between speed, torque and horsepower. Torque is constant at any speed while there is a direct proportional relationship between horsepower and speed; horsepower varies directly with the speed. Therefore, horsepower is motion dependent, torque is not.

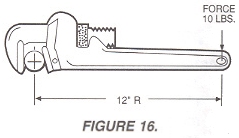

TORQUE

A force applied in a manner that tends to produce rotation, such as a pipe wrench on a shaft. Torque (force) without rotation is termed static torque, since no motion is produced.

Because most power transmission is based upon rotating elements,

torque is important as a measurement of the eftort required to produce work (horsepower).

POWER (Horsepower)

A force applied in a manner that produces motion and, therefore, work over a specified time period. A common unit of power is horsepower. One horsepower (HP) is defined as the force required to lift 33,000 Ibs, one foot in one minute.

Three basic factors are involved:

| Factor | Unit | |||

| Distance (Radius) | Foot (or inches) | |||

| Force (Push or Pull) | Pounds | |||

| Time | One (1) Minute | |||

|

||||

HORSEPOWER-TORQUE, GETTING IT TOGETHER

As shown in Figure 17, the 50 lb load is acting on the 5 inch radius (distance) of the winch, producing a load torque of 250 lb-in (50 lbs x 5 inches) that must be overcome to lift the load. Since the hand crank arm has a 10 inch radius (distance), a minimum force of 25 lbs must be exerted to overcome the load torque (25 lbs x 10″ = 250 lb/in). If no motion is involved, the system is in balance. Although torque is being exerted, no work is accomplished and no horsepower is developed.

The winch diameter is 10 inches. Therefore, each revolution of the hand crank will lift the weight 10 inches X = 31.416 inches (2.618 feet).

If the crank is turned at 10 RPM, 50 Ibs will be lifted a distance of 26.18 feet in one minute:

|

HP = |

Load in pounds x Feet per Minute |

| 33,000 | |

|

HP = |

50 x 26.18 | = .03966 HP |

| 33,000 |

Turning the crank twice as fast (20 RPM) will develop twice the horsepower.

|

HP = |

50 x 52.36 | = .07933 HP |

| 33,000 |

Thus, the horsepower of rotating elements can be calculated from the following formula:

|

HP = |

F x 2 |

= |

T x RPM |

| 33,000 |

5252 |

where,

F = force in pounds

R = radius (lever length in feet)

RPM or N = revolutions per minute

T = torque in lb/ft (F x R)

SELECTING A DRIVE FOR A MACHINE

The application of an adjustable speed drive to power a machine is a mechanical, rather than an electrical problem. When applying the drive, ” the speedltorque/horsepower characteristics developed at the drive : motor shaft must be considered, and how well these characteristics suit the machine. Four essential parameters are: Breakaway Torque, Process Torque, Accelerating Torque and Running Torque.

BREAKAWAY TORQUE

The torque required to start the machine in motion. It is most always greater than the torque required to maintain motion (running torque). Breakaway torque combined with process torque frequently determines drive selection. Table 5 lists typical breakaway torques for various machine types.

TABLE 5. TYPICAL BREAKAWAY TORQUES FOR VARIOUS MACHINE TYPES

| Machine Type | Breakaway Torque(1) | Drive Selection |

| Machines with ball or roller bearings | 110 to 125% | Standard drive rating |

| Machines with sleeve bearings | 130 to 150% | Standard drive rating |

| Conveyors and machines with excessive sliding friction | 160 to 250% | Oversize drive |

| Machines that have “high” load spots in their cycle, e.g., printing and punch presses, and machines with cam or crank operated mechanisms. | 250 to 600% | Oversize drive |

| high Inertia – Machines with flywheels or other heavy rotating masses. Also, some machines that move large masses by cranks, centrifuges, etc. | Nominal rating of drive will depend on the breakaway torque requirements | Drive rating dependent upon desired acceleration time and drive torque |

NOTE: (1) Typical percentages of running torque

PROCESS TORQUE

The torque required to pull, push, compress, stretch or otherwise process or act upon the material being transported by or through the machine. On some machines, process torque may be so significant as to determine the drive power rating. On other machines, this load may be insignificant. The process torque load is superimposed on all other static and dynamic torque requirements of the machine.

ACCELERATING TORQUE

The torque required to bring the machine to an operating speed within a given time. With most machines, the load is largely friction and a standard drive rating may have adequate torque for satisfactory acceleration. However, certain machines classified as “high inertia” with flywheels, bull gears or other large rotating masses may require drive selection based upon the power required to accelerate the load within a given time.

RUNNING TORQUE

The torque required to maintain machine motion after it accelerates to the desired operating speed. The characteristics of the speedtorque curves of various machines are very important to proper adjustable speed drive selection. Virtually all machines fall into four basic categories which provide common and useful classifications for machine types: Constant Torque (Figure 18), Constant Horsepower (Figure 19), Squared Exponential Horsepower (Figure 20), and Cubed Exponential Horsepower (Figure 21).

A limited number of machines may have operating characteristics which are a composite of the basic types.

|

|

|

|

Constant Torque – About 90% of all general industrial machines, other than pumps, are constant torque systems. The machine’s torque requirement is independent of its speed. If the machine speed is doubled, its horsepower requirement doubles. This fact is commonly overlooked when replacing a constant speed drive with an adjustable speed drive and the machine operating speed is increased.

Constant Horsepower – For machines with constant horsepower loads, the power demand is independent of speed, and torque varies inversely with speed. This type is most often found in the machinetool industry and with center driven winders. When drilling, shaping, milling, or turning metal, the loads all tend toward constant horsepower. At low speed there is high torque; at high speed, light torque. A drive must be selected for its highest torque condition which is at the lowest speed of the range. With most machines, the “constant horsepower range” seldom covers even a 3:1 range, though some applications may require 5:1 or more.

Squared-Exponential Loads – With machines of this type, torque varies directly as the speed, and power as the square of speed. Such relationships are frequently found in positive-displacement pumps and mixer applications.

Cubed-Exponential Loads – It is a characteristic of these machines that torque varies as the square of speed, and power as the cube of speed. This type of load is imposed on centrifugal pump drives and most fan or blower drives. In some uses, fan or blower horsepower varies as the fifth power of speed. The exponential relationship is characteristic of these machines. This fact must be considered when sizing motors for adjustable speed drives. If the speed of a centrifugal pump is doubled, its power requirement increases by a factor of eight.

Adjustable Speed Drive Application Information provided by: FINCOR Automation