Adjustable speed drives are rated by their manufacturers to conduct a specified amount of current under specified conditions. While each manufacturer sets their own specifications, ratings generally share these common characteristics:

- Drive PWM carrier (switching) frequency: There is variation here among manufacturers, but rated current output is based on a set carrier frequency. If that frequency is adjusted upward, de-rating is required.

- Maximum ambient temperature: typically 40C, with a 1% drop in rated current for each degree from 41C to 50C. Most manufacturers will not rate their drives for operation above 50C. Ambient temperature is of course related to installation method, and so sometimes these two factors are taken together to generate a single de-rating factor. That is the case with Yaskawa drives in the examples below.

- Installation spacing: although there is more variation among manufacturers here than with other factors, to obtain full-rated current the drive will typically need to be installed with a clearance of 100mm above and below, to allow proper ventilation airflow (usually from bottom to top), and from 0 – 30mm side clearance. If the drive is self-contained, the type of enclosure will also factor into this.

- Altitude: due to the decreased cooling capacity of less dense air, drives are usually designed to conduct rated current at an altitude of 1000m or lower. Altitudes higher than this require drive current de-rating by a factor of 1% for every 100m above 1000m.

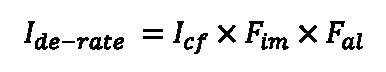

Let’s look at specific examples from the 1000-series of drives manufactured by Yaskawa – their model groups A1000, J1000, and V1000. First – and this is typical of nearly all manufacturers – with the exception of some of the smaller drives the rated current output varies based on whether the drive is applied to a variable torque (normal duty) or a constant torque (heavy duty) application. So for example, the Yaskawa A1000 25 HP/20 HP drive #CIMR-AU4A0038 is rated for continuous output current of 38 amps at 380 – 480 volts in a normal duty application under specified operating conditions. Under heavy duty conditions, the same drive is rated for 31 amps continuous output. This lower rated output is intended to provide headroom for the higher current draw (i.e. a higher overload capacity) due to the higher torque usually needed for heavy duty starting conditions. In either case, rated currents must be lowered (de-rated) if other than specified operating conditions exist. The de-rating factor is defined as:

where: Ide-rate = continuous output current capacity under de-rated conditionsIcf = Rated current at selected carrier frequencyFim = % de-rating due to ambient temperature and installation methodFal = % de-rating due to altitude

Note that the equation takes into consideration multiple de-rating factors. Taking each individually for the 25 HP, 38 amp normal duty drive noted above:

- Icf: The carrier frequency for this drive at rated output current is 2 kHZ. If instead a carrier frequency of 8 kHz is desired, the output current rating drops to 31 amps.

- Fim: If the drive is operating in an ambient temperature of, say, 50C, and is installed in a NEMA 1/IP20 enclosure, then the rated current must be reduced by 15%. For example, the rated current of the above drive operating at an 8 kHz carrier frequency, installed in a NEMA 1 enclosure at an ambient of 50C is now 26.4 amps (31 * .85). (Note that this is an example of two factors – ambient temperature and installation type – compounding to increase the de-rating factor beyond what either one alone would dictate.)

- Fal: If the same drive above were located at an altitude of 2000m, that 26.4 amps would be further reduced by 10%, or 26.4 * .90 = 23.8 amps.

One other note of caution…although manufacturer specifications state full-rated current up to specified conditions, you can also expect drive life to be reduced to some degree if you regularly operate at full-rated output at or near the upper limits of specified temperature and altitude. If that is where you expect to operate, it is worth considering to increase the drive size in order to gain a few more years’ worth of operation.

If you would like to share your application experiences, please drop by our Comments section. If you would like assistance with the proper drive for your application, please call, email us at info@joliettech.com, or visit us at joliettech.com/blog and joliettech.com. We’ll be glad to assist. And please remember to join me in two weeks for another column. “See” you then!

Regards,

Jay Baima

Joliet Technologies

Leave A Comment

You must be logged in to post a comment.