In the last article, we spoke about the requirements-based design and engineering that go into the fabrication of a high-quality, custom-built control panel. Much of this necessarily happens “behind the scenes”, well before a panel is assembled, but when you’re in the process of choosing a panel fabricator all you may have to go on is the “look and feel” of examples being advertised. So, whether you’re online searching panel builders’ sites, or in the field reviewing build quality, what should you look for in a quality custom-built control panel? Let’s examine the most common things to watch for.

- Workmanship: They say “neatness counts”, and this is doubly true for control panel fabrication. A clean, well-managed, orderly layout makes maintenance and trouble-shooting far easier, saving time and money. Keys to look for:

- Components properly anchored and laid out in a logical fashion

- Wires neatly bundled and routed with minimal interference, and meeting minimum bending radius requirements

- Clearances maintained for ease of access and adequate ventilation

- Consistent wire coloring scheme

- Covers in place and fastened properly

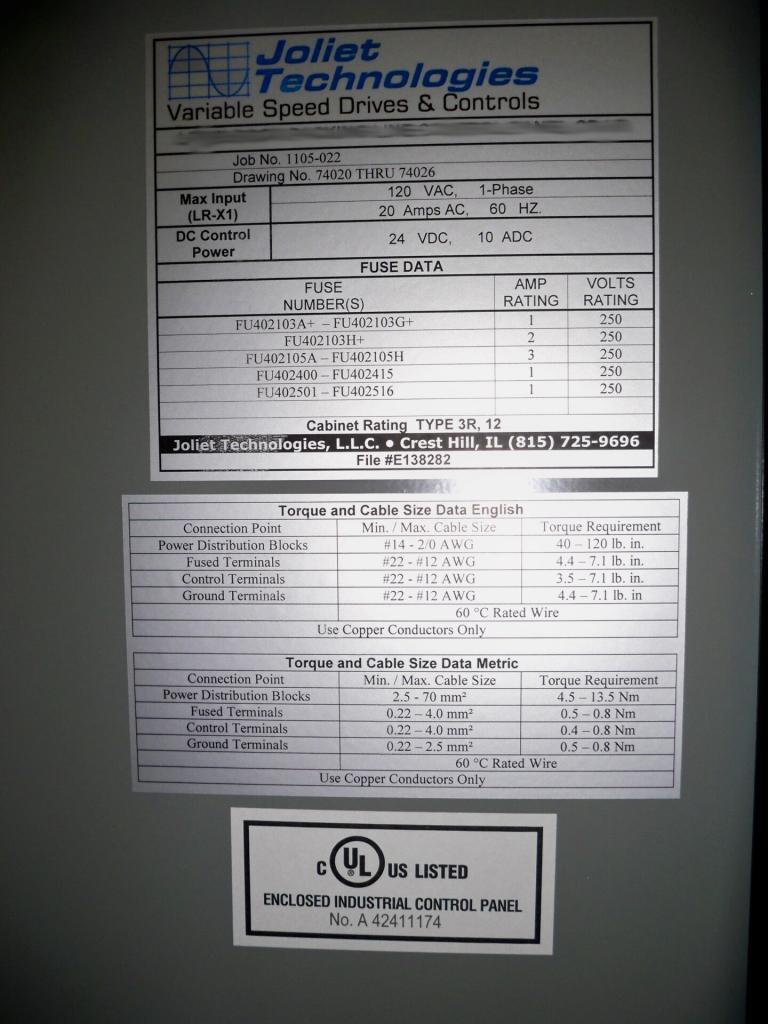

- Labeling: One of the first, and easiest, things to note is whether there are clear, descriptive rating and compliance labels on the control cabinet. A UL508 compliance label will tell you that the panel was built and tested to rigorous UL standards, but this may not be required for a given panel. In all cases, however, a ratings label should be provided and should indicate the following at a minimum:

- Supply rating – phase/frequency/voltage and current (protective device rating or maximum amperage draw, as applicable)

- Supply circuit location and data, if known

- Short circuit current rating (SCCR) – in kilo-amps at rated voltage

- Control power – phase/frequency/voltage and current, and source of supply (if externally sourced)

- Rated output – in the case of a variable speed drive or reduced voltage (soft-start) cabinet

- Over-current protection data (i.e. fuses or CB, type, and trip rating)

- Ingress protection rating of the built enclosure (IP or NEMA, as applicable)

- References to drawings, manuals as applicable – with build revision and date

- Internal layout: While component layout can sometimes be a matter of builder preference, there are some recognized high-quality standards and practices to look for. These include:

- Compliance with minimum wire bending radius, which is primarily a concern with larger power supply conductors

- Adequate clearance around components for access and cooling

- Proper segregation of power, control, and signal circuits. While this is required by code, the means of separation can vary, and some are better than others. This can be especially important in heavily regulated environments such as the nuclear industry, where clear definition and segregation of Class 1E circuits is mandatory per IEEE 384. Adherence to minimum distances of separation depends heavily on the knowledge and experience of the panel builder.

- Ease of access to terminal strips and power blocks for wiring termination

- Logical grouping of functionally related components to facilitate identification and trouble shooting

- Proper mounting of components and the use of vibration dampeners, where applicable

- The use of covers or other means to protect workers from contact with live circuits

- Cabinet fit/finish: If the cabinet is new, is its finish smooth, free of abrasions/scratches, dents, etc.? Where applicable, are door gaskets, hinges, door stops, and drip shields in place and functioning properly? If supplemental cooling is provided, are housings, vents and grills in place and fastened properly? Are lifting eyes/brackets in place (where applicable)?

- Documentation: Examine the documentation shipped with the panel. Is a full test report included? Have as-built drawings and reference manuals been provided? Have manufacturers’ datasheets/instructions been provided for key internal components?

By keeping the above information top of mind, you’ll be able to recognize a high quality control panel at a glance. Please feel free to drop me a comment or question in the Comments section if I can be of further help. And now that you know what to look for, please contact us with any panel or drive needs – visit us at JolietTech.com, email us (info@joliettech.com), or call 866.492.9888. Thanks for reading!

Regards,

Jay Baima

Joliet Technologies

Leave A Comment

You must be logged in to post a comment.