Much has been discussed of the additional stresses that variable speed drives (VSD’s) can place on motor leads and insulation systems. However, in all but the most sensitive of installations, and assuming the use of properly rated motors, preventive or corrective measures are readily applied, especially during design and engineering stages. While each VSD and motor manufacturer has specific requirements for cabling design and installation practices, there are several elements common to all.

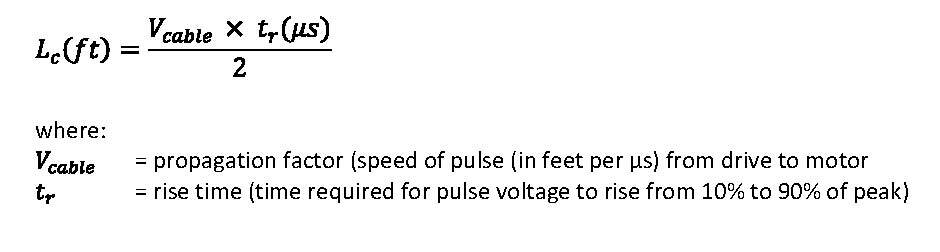

- Limiting motor lead length: by installing drives as close as practical to the motors they control, the magnitude of voltage overshoot is reduced, lessening the risk of over-voltage at the motor terminals (all other things being equal). There is a length, generally referred to as the critical length, beyond which the magnitude of reflected voltage pulses increases to the the extent that motor insulation systems can be affected. Critical length varies based on cable and drive characteristics and is calculated as:

The critical length is a consequence of the rate of travel of the pulse from the drive to the motor versus the rise time of subsequent pulses output by the drive. If the travel time is slower than 1/2 of the rise time, then the energy reflected from the motor terminals adds to the subsequent output pulse, increasing the overall voltage level. A rough guideline for cable propagation might be 500 feet per mu-sec, which with a typical pulse rise time of 0.1 mu-sec for IGBT output drives, results in a critical length of 25 feet. In practice, problems are rarely seen at this length unless the motor insulation system is very weak. However, it does point out the fact that with modern PWM drives, care must be taken when designing and locating equipment.

- Use of shielded cabling: Although in many cases individual non-shielded phase conductors can be used if installed in metallic raceway and properly routed, most manufacturers recommended shielded (screened) cable for effective reduction of electromagnetic interference (EMI). Motor leads are long enough to serve as an excellent antenna capable of radiating large amounts of EMI, which is produced as a function of the high-frequency switching of the drive inverter section. Empirical evidence shows that the lower the cable’s transfer impedance (a measure of the cable’s shielding capability) the greater the EMI reduction. This limits the noise propagated to adjacent sensitive equipment and, more importantly, any control conductors in the vicinity. Numerous cases exist of faulty sensor performance as a result of EMI-induced cross-talk from unshielded power conductors routed close to and/or parallel to low-amplitude signal control wiring.

Equally important is the proper termination of the cable shields. It is recommended that shields for motor leads be landed at both the motor AND drive end, and that 360-degree clamp connections be used to bond the full extent of the shields. Pig-tailing the shield and landing it on a bonding screw is not advised, since this increases the cable’s impedance to high-frequency currents and causes voltage on the cable to rise.

Many of these issues are complex in and of themselves and are suitable for future columns. In the meantime, please contact us for additional information at info@joliettech.com, or respond in our Comments section. You can also visit our web site (joliettech.com) or call us at 815.725.9696. Have a great week, and thanks for reading!

Regards,

Jay Baima

Joliet Technologies

Leave A Comment

You must be logged in to post a comment.