What to Look for in a Quality Custom-Built Control Panel

In the last article, we spoke about the requirements-based design and engineering that go into the fabrication of a high-quality, custom-built control panel. Much of this necessarily happens “behind the scenes”, well before a panel is assembled, but when you’re in the process of choosing a panel fabricator all you may have to go on is the “look and feel” of examples being advertised. So, whether you’re online searching panel builders’ sites, or in the field reviewing build quality, what should you look for in a quality custom-built control panel? Let’s examine the most common things to watch for.

- Workmanship: They say “neatness counts”, and this is doubly true for control panel fabrication. A clean, well-managed, orderly layout makes maintenance and trouble-shooting far easier, saving time and money. Keys to look for:

- Components properly anchored and laid out in a logical fashion

- Wires neatly bundled and routed with minimal interference, and meeting minimum bending radius requirements

- Clearances maintained for ease of access and adequate ventilation

- Consistent wire coloring scheme

- Covers in place and fastened properly

Fig. 1 – Drive Module (ACS880 series) Courtesy of ABB Inc.

Fig. 1 – Drive Module (ACS880 series) Courtesy of ABB Inc.

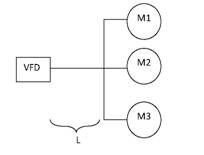

A: The most important consideration in the case of multiple motors connected to a single drive is the length of the leads between the VFD and the point of common connection of the

A: The most important consideration in the case of multiple motors connected to a single drive is the length of the leads between the VFD and the point of common connection of the