The Impact of Electric Motor Controls on Industrial Automation

The integration of electric motors into industrial automation has revolutionized the way industries operate, offering numerous benefits such as enhanced efficiency, improved safety, and increased productivity.

Electric motors are pivotal in transforming electrical energy into mechanical energy, which is essential for the functioning of various industrial machinery. This transformation has led to significant advancements in manufacturing processes, allowing for precise control and optimization of operations.

One of the key benefits of using electric motors in industrial automation is their ability to improve energy efficiency. By optimizing the power usage, these motors help industries reduce operational costs and minimize environmental impact. Additionally, the use of Variable Frequency Drives (VFDs) in conjunction with electric motors further enhances this efficiency by allowing precise control over motor speed and torque.

Furthermore, electric motors contribute to improved process control. They enable precise adjustments in speed and torque, which are crucial for maintaining product quality and consistency. The capability to monitor and adjust these parameters in real-time allows for more agile and responsive manufacturing processes.

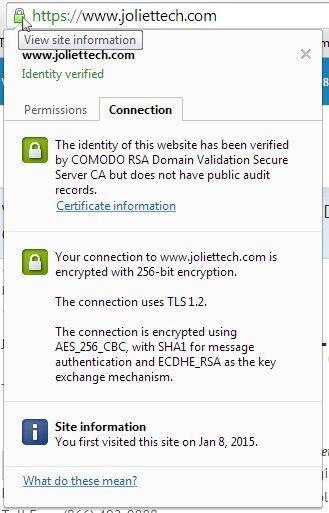

At Joliet Technologies, we specialize in providing customized Variable Frequency Drive systems that cater to your specific industrial needs. Our […]